Don’t let that put you off, though-you certainly don’t need to be a code breaker to work with these tools! Rather than writing the G-Code yourself, or attempting to modify existing G-Code, you have the option of using CAM software or CAD editing programs to produce the code.ĬNC projects can be fun, satisfying and educational.

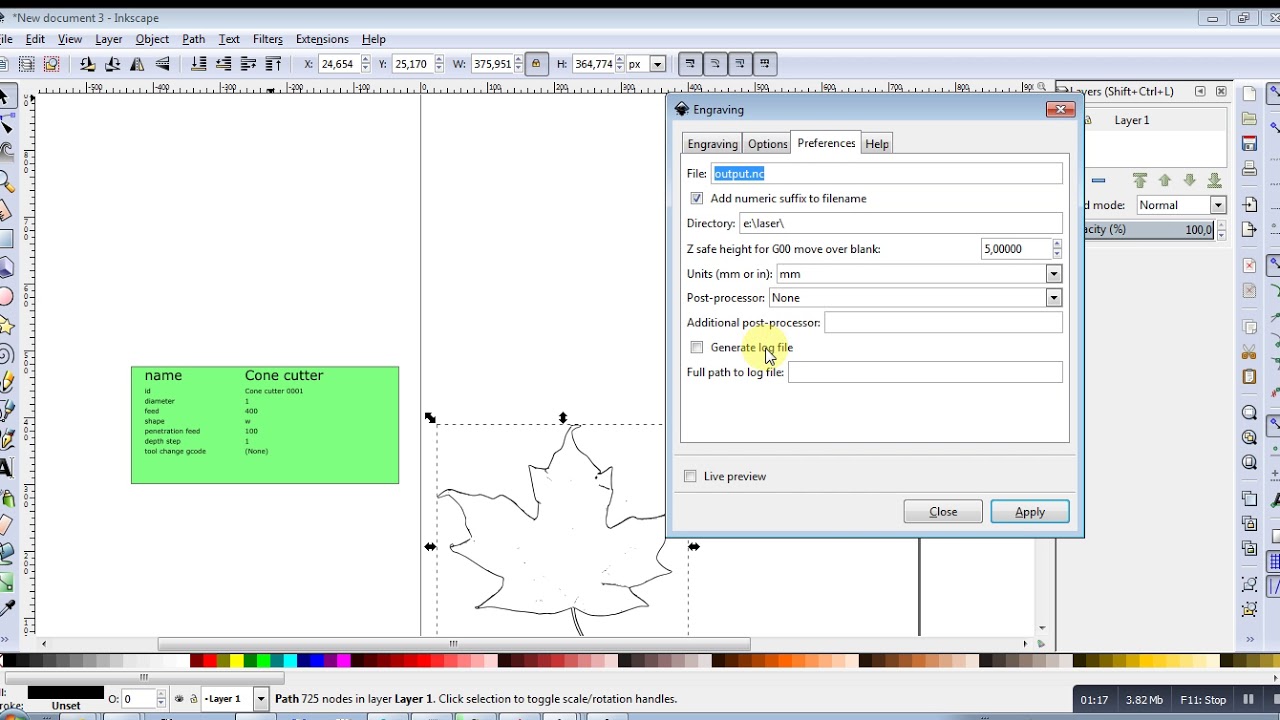

The G-Code itself looks quite complex and can be intimidating if you’re new to CNC. As you can imagine, it’s not easy to write the code yourself unless you’re an experienced CAM programmer! Using what are called Cartesian coordinate locations, the machine is fed instructions including direction, speed and depth-thus enabling it to create products from a computer image.Īn example of G-Code within a CNC editor. In terms of the former, G-Code tells CNC machines where and how to move.

It’s largely associated with CNC machines, but can also be used in 3D printing and photoplotting. G-Code is a programming language made up of letters and digits. DXF files are a sound choice if you’re working with 2D vector images, and a great starting point if you’re looking to convert to G-Code. The files have an open source format and enable people to access AutoCAD drawings, for instance, without the need to use Autodesk applications. Created in 1982 by Autodesk, it’s particularly useful for sharing designs across different CAD programs. Indeed, the full name for this file type is actually Design e Xchange Format.

0 kommentar(er)

0 kommentar(er)